THIN FILM DRYER NDS TYPE

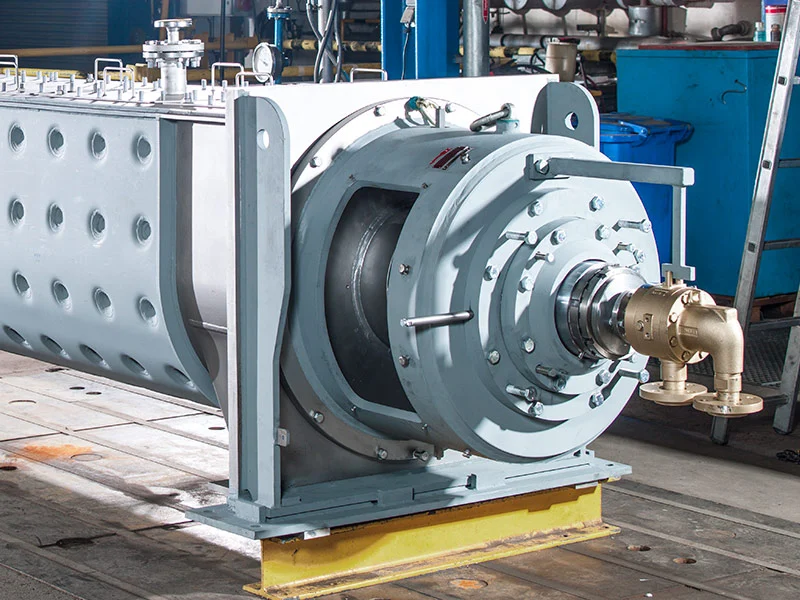

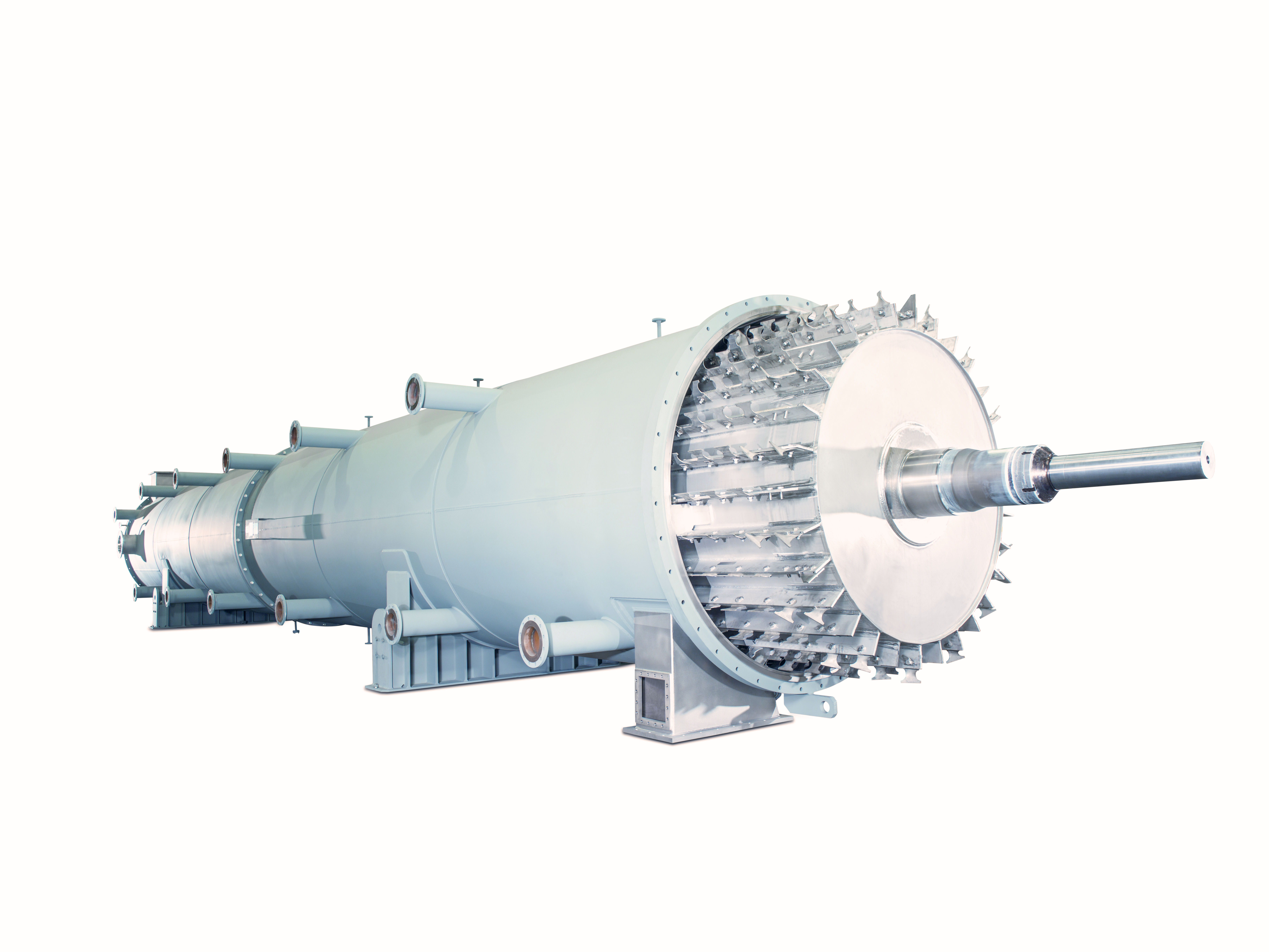

Drying is carried out in a single pass TFD type NDS. Water will be evaporated and the sludge will be dried to a dry solid content as described separately. In the dryer, the wet sludge is immediately taken up by the rotating rotor blades, evenly distributed as a thin film on the heat transfer surface and simultaneously transported out of the dryer.

The horizontal jacketed wall is the heating surface to which the sludge is applied in a thin layer by the dryer rotor elements. The dryer barrel housing is jacketed and heated by steam.

The arrangement of the rotor blades can be adjusted for the best performance of the given sludge after the dryer has been installed. The dryer is supplied with an arrangement to the best of the manufacturer's knowledge and is normally well adapted.

The dried sludge is discharged from the dryer by gravity through a vertical outlet nozzle at the opposite end of the wet sludge feed point.

The dry matter content at the dryer inlet and outlet should be measured regularly. If the dry solids content at the dryer inlet or outlet is outside the design range, the heating temperature or the feed rate should be adjusted.

The power consumption rate of the dryer rotor drive system is controlled to protect the drying system from overloading. If the charge rate exceeds a certain level for a certain period of time, the feed rate to the dryer is automatically reduced to predefined levels.

Drying is carried out in a single pass TFD type NDS. Water will be evaporated and the sludge will be dried to a dry solid content as described separately. In the dryer, the wet sludge is immediately taken up by the rotating rotor blades, evenly distributed as a thin film on the heat transfer surface and simultaneously transported out of the dryer.

The horizontal jacketed wall is the heating surface to which the sludge is applied in a thin layer by the dryer rotor elements. The dryer barrel housing is jacketed and heated by steam.

The arrangement of the rotor blades can be adjusted for the best performance of the given sludge after the dryer has been installed. The dryer is supplied with an arrangement to the best of the manufacturer's knowledge and is normally well adapted.

The dried sludge is discharged from the dryer by gravity through a vertical outlet nozzle at the opposite end of the wet sludge feed point.

The dry matter content at the dryer inlet and outlet should be measured regularly. If the dry solids content at the dryer inlet or outlet is outside the design range, the heating temperature or the feed rate should be adjusted.

The power consumption rate of the dryer rotor drive system is controlled to protect the drying system from overloading. If the charge rate exceeds a certain level for a certain period of time, the feed rate to the dryer is automatically reduced to predefined levels.

.png)